The 19th-century invention of the solenoid (or solenoid switch) by French physicist André-Marie Ampère and ASCO Numatics’ development of the solenoid valve in 1910 are, perhaps, among the most (if not the most) important breakthroughs of the last two centuries. Not only did they shape life-saving equipment and modern conveniences, but daily commuters and hobbyists also have them to thank for their wheelers.

What is a solenoid switch? A solenoid switch is a part of the starter relay circuit responsible for actuating the switch that fires up your car’s engine. This small component is also widely used in industrial, medical, and domestic applications such as wide-scale engines, patient monitors, and sprinkler systems.

The solenoid switch is a versatile solution for regulating power flow, mechanical interlocks, or electromagnetic switches. But like most end users, you may find yourself asking, “What does a solenoid do?”, “Does a solenoid act as a switch?” and “How do you know if you have a bad solenoid?”.

If so, continue reading this guide to find out the answers to these questions.

Solenoid Definition

A solenoid is a generic term that refers to a coil of wire used as an electromagnet or any device that converts electrical energy to mechanical energy. It is usually mated to relays designed for large electric currents, connecting the battery to the starter motor.

Door locks, speakers, MRI machines, water-pressure valves, and disk drives are some of the most common things solenoids are used for. Various applications are used in the medical, industrial, and automotive fields. In general, there are five (5) types of solenoids, namely:

- Rotary solenoid

- DC-C frame solenoid

- DC-D frame solenoid

- AC-laminated solenoid

- Linear solenoid

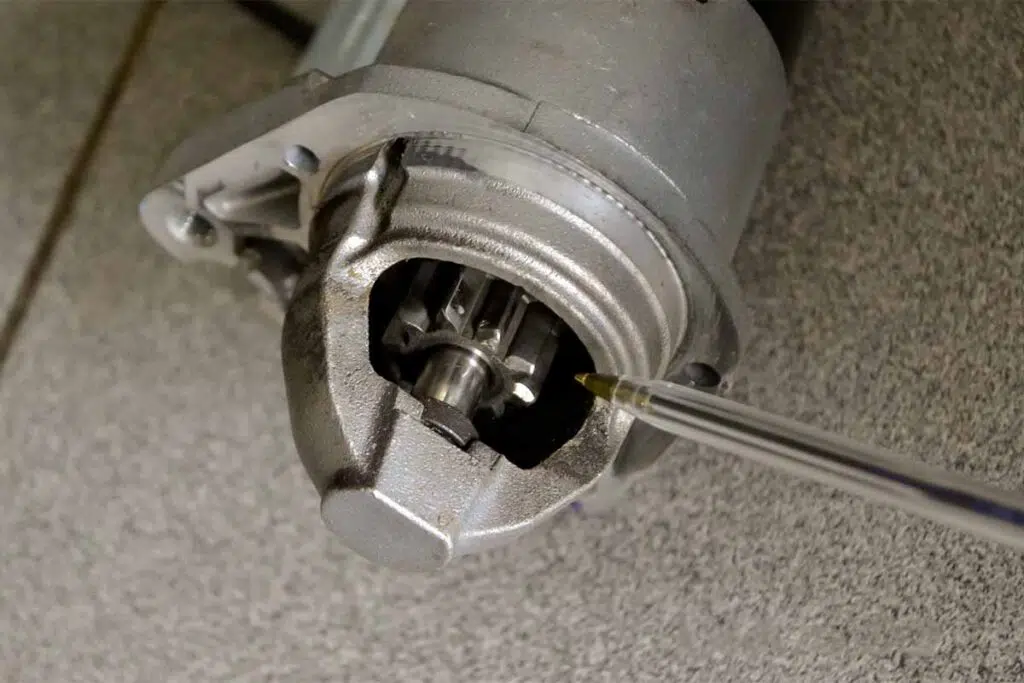

The last two types are what is in use in most vehicles. A starter solenoid (an important component of your car’s ignition system) is an example of a linear solenoid, also referred to as an electric or intermittent solenoid. It is usually found between the ignition and the engine or mounted on the fender well, firewall, or underside of the engine.

Other solenoid types include the following:

- Canister purge valve (EVAP) solenoid

- Tailgate lock solenoid

- EGR valve solenoid

- Shift interlock solenoid

- Downshift solenoid

They fall under either of these two categories.

Solenoids vs. Electromagnets

Because of the purpose it serves, solenoids are often thought to be the same thing as electromagnets. While they do have similarities in their working principle, they are two different things.

A solenoid, by itself, is only a coil of wire – it only becomes an electromagnet when you run a current through it. This mechanism renders a solenoid very useful and essentially better than a permanent magnet.

Its electromagnetism can be made stronger by increasing the current flow through it or the density of the coil’s turns. It can also switch on and off.

The Solenoid Switch

With any of the abovementioned solenoid types, remote control of high-current flow is required. And this is where the solenoid switch or solenoid valve enters the picture.

In the case of vehicles, this switch goes into action the moment the ignition key activates. It utilizes smaller electrical control signals from the ignition system.

In turn, these signals connect the battery to the drive pinion of the starter motor circuit and turn the starter motor on and off. The solenoid switch’s intelligent nature employs decision-making and extensive logic circuits to make this entire process possible.

The solenoid switch valve is part and parcel of any solenoid design that allows for more efficient management of power required by a vehicle to start. Depending on the make and model of your car (and the design of its electrical components), it may have one of six solenoid switch valve types.

Valve Types

- Two-way Valves – can be deployed in various applications. They alternately permit and shut off inflow and remain open until current is applied to close the valves.

- Direct-acting Valves (2/2 Direct Operated Valves) – have the simplest working principle. When valves are open or energized, the coil magnetically lifts the shaft and valve seat. Without the aid of outside pressure, these valves remain fully operational all the time. Thread size is 0.125 – 0.5 inches.

- Assisted-lift Valves (2/2 Semi-direct Operated Valves) – have combined properties of both direct and indirect solenoid valves. They feature a small orifice, a movable membrane, and pressure chambers on both sides. But unlike indirect valves, the solenoid plunger directly connects to the membrane. This mechanism, among other things, makes this valve type capable of controlling relatively large flow rates. The thread size is 0.125 – 4.0 inches.

- Pilot-operated Valves (2/2 Indirect Operated Valves) – require less energy to operate but need to maintain full power to perform at a slower rate and remain in an open state. The thread size is 0.5 – 4.0 inches.

- Three-way Valves (2/3 Solenoid Valves) – used to operate single-acting actuators and comes with three ports – the first is for the valve inlet, the second is for the outlet, and the third is for the exhaust.

- Four-/Five-way Valves (2/5 Solenoid Valves) – provides two-directional action. These valves provide intermittent operation of double-acting valves with a dual-acting cylinder or actuator.

Regardless of your vehicle’s valve type, a solenoid switch valve will deteriorate over time. Factors such as exposure to transmission fluid or metal salts and fluctuations in temperature or weather conditions often hasten the process.

That said, recognizing when a solenoid has gone bad is just as important as giving your vehicle components proper care and maintenance.

Starter Solenoid Problems

A starter solenoid can hold up to 200V and would have no problems bringing your vehicle to life with the turn of the ignition key. So, if you only hear a click, a loud screeching sound, or silence when starting your car, you know there is a problem.

Of course, you will have to test your battery to make sure. But if the battery checks out, this confirms your issue with the starter solenoid switch.

Most starter solenoid problems are due to worn or burnt solenoid contacts or armature bushings. A starter motor that does not run but is accompanied by clicking sounds would indicate worn-out solenoid contacts.

Meanwhile, a no-start occurrence in complete silence would point to damaged starter brushes. If you are getting the slow, loud starter motor noise, the front and rear armature bushings are the issue.

Other known symptoms include the starter solenoid’s failure to reset, failing sucking action, the solenoid’s inability to work up the starter and cause rotation, a no-turnover despite a running starter motor, and erratic engine starting.

Error Codes

There are instances when the Check Engine Light comes on, along with several trouble codes. The most common error codes indicating a starter solenoid or relay issue are as follows:

- P0615 – Starter Relay Circuit

- P0616 – Starter Relay Circuit Low

- P0617 – Starter Relay Circuit High

If only P0615 shows, you are most likely dealing with a bad starter solenoid. If two or more trouble codes appear, you may have to inspect several components in the starter circuit.

Conversely, you may want to consider a faulty ignition switch, starter motor, or wiring in the absence of an error code. Do not forget that excessive heating and moisture, as well as overtightening of bolts and fasteners, also cause a starter solenoid to go bad.

Transmission Solenoid Switch Problems

Strange problems with shifting or unexpected error messages on the dash are but a few of the telltale signs pointing to a faulty shift or transmission solenoid.

But because replacing it can be costly – between $400 to $1,000 for a full transmission solenoid kit, including valve body replacement – make sure that you are getting these specific symptoms before proceeding with the following steps:

- Check Engine Light (usually comes with a P0700 trouble code)

- Transmission warning light (only applicable for certain vehicles and may pertain to a stored trouble code)

- Downshift/upshift problems (you may experience delayed shifting or extremely high/low RPMs)

- Difficulty in engaging/skipping gears (one of the biggest indications of a shift solenoid problem)

- Stuck in gear (indicates a solenoid got damaged while a specific gear was engaged)

- Limp mode (you can only shift up to 3rd gear and cannot go beyond 2,500 – 3.000 RPM

The check engine light does not always point to a defective transmission solenoid, as a faulty VVT solenoid or Variable Valve Timing solenoid also has the same symptom. Use a diagnostic scanner to ascertain it is the right non-working solenoid you are replacing.

TIP: Bad VVT solenoid symptoms usually include reduced fuel economy, rough idling, or power loss alongside the Check Engine Light coming on. On rare occasions, a simple transmission flush rectifies the problem.

How to Test a Solenoid

Testing a solenoid largely depends on the kind of solenoid suspected to have fault – methods used on an on/off type and a regulating type will be dissimilar.

On/off solenoids are less complex. Pressure should apply individually to its inlet and outlet when the solenoid is normally closed or normally open.

A normally closed valve (the position where it blocks oil or current from flowing from the inlet to the outlet) with pressure applied to the inlet should have no pressure at the outlet. The reverse should be true if the solenoid is normally open (the solenoid valve position where it allows oil or current to flow from the inlet to the outlet).

Conversely, regulating solenoids will yield different results when tested and would be less keen to excessive inlet pressure – unlike the former.

As for testing methods, the simplest way to energize an electrical solenoid is to do so with ignition voltage until it draws full current. The second most preferred technique is using PWM or Pulse Width Modulation and employing the “peak and hold” process.

Refer to your owner’s manual for specific, technical procedures that will help diagnose and rectify problems with your vehicle’s solenoid switches. For beginner mechanics who wish to perform first-line troubleshooting on suspected solenoid coils, refer to the steps below.

1. Check the Battery First to Make Sure It Is Not the Culprit.

Set the voltmeter to a range higher than the battery voltage when doing this test. A reading between 12.4V and 12.6V means the battery is amply charged. If your reading is within this range, proceed to the next step.

2. Do the “Click Test.”

You perform this by having a friend start the car while you are at a safe distance from where the solenoid is located. A weak or repetitive sound (or the lack of) could mean that your solenoid is either underpowered or defective.

3. Check the Voltage on Your Solenoid With the Use of a Multimeter.

If you have an automatic multimeter, set it on ohms. If you do not, manually set it to 2k ohms.

4. Place the Multimeter Probes Across the Pins of the Solenoid Coil.

If you are working on a coil with three (3) pins, leave the flat one out and connect the other two pins with the multimeter.

5. Attach the Wires.

Attach the positive wire from the multimeter to the positive terminal and the negative wire to the corresponding terminal. Have a friend start the engine again – there should be a voltage drop when the ignition turns on.

6. Note the Readings.

Note the readings on the multimeter and see if the coil resistance falls within the manufacturer-recommended range. Getting a reading of 0 ohms would mean the solenoid coil is shorted, while an infinity reading would mean the coil is broken.

You may get a normal reading on the multimeter in some cases, but the solenoid coil is not functioning. When this happens, test the coil with the use of a screwdriver.

Place the screwdriver near the armature, then energize the solenoid. Sensing the presence of a magnetic force would mean the coil is good. Otherwise, you will need a replacement.

Out of all the testing apparatuses available today, a hydraulic solenoid testing machine (with specific adapters for each solenoid) is the most accurate and, by far, the best tool to use. Not only is the application of this machine encompassing, but it also comes with a guide on how to go about the testing process.

But unless you have your own auto shop, it would not be bad to settle for a multimeter, jumper cables, and protective gear, and eyewear to be able to perform tests on a faulty solenoid coil.

Frequently Asked Questions:

Can you bypass a starter solenoid?

Yes. You can bypass a starter solenoid. Start by locating the starter wire and jumper wire connected to the metal contact at the back of the starter solenoid.

Then, place the metal blade of an insulated screwdriver across the two metal contacts to directly connect the ignition switch and the starter motor. Doing this will only help troubleshoot or narrow down the cause of your no-start issue but would be of no benefit in starting the engine.

How do you fix a stuck starter solenoid?

Tap the back of the solenoid with a hammer or a heavy screwdriver. While this may temporarily get the solenoid unstuck, it is not advisable, as you may end up damaging the starter solenoid more than fixing it.

Refer to your manual or a local mechanic for manufacturer-recommended solutions.

Can you jump a bad solenoid?

You can. However, this will only work alongside an aptly charged battery with enough current to turn the starter motor. Otherwise, jumping a bad starter solenoid will make no difference in getting your engine started.

Conclusion – Solenoid Switch (Definition & Guide)

The solenoid switch is vital to proper automotive function. Knowing how to diagnose and address any issues with it is just as important as doing the same for larger vehicle components such as the battery, transmission, and engine.

Wiring, starter circuits, and power systems can be challenging to wrap your head around. But with the help of this article, you should be able to address solenoid switch problems with newfound confidence.

Kris is an avid off-roader and outdoor enthusiast who loves to brave the elements and take on challenging terrain. He also enjoys sharing his passion and knowledge with others so that they, too, can appreciate the ride.

About Kris