Noise from the suspension is probably one of the most worrisome sounds you will hear from your vehicle. Many car owners consider it a bad omen because of what it signifies. That rattling, grinding, or humming sound while ripping through the freeway or turning a corner can only mean one thing — either a suspension component or the entire system is impaired and needs immediate servicing.

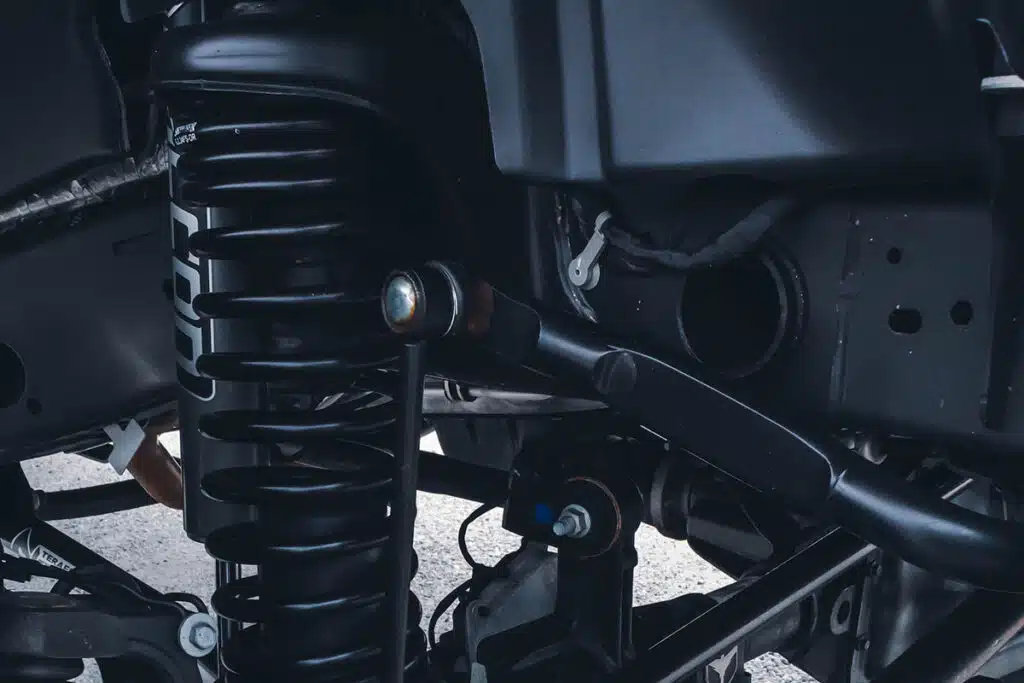

The suspension system generates unusual noises whenever one or more parts are compromised. This noise may come from the A-arms, wheel bearings, mounting hardware, or struts. Depending on the cause of the noise and the damage incurred, repair or replacement of the affected part may be required.

For a detailed rundown, here is a list of the most prevalent causes of noise from the suspension:

- Damaged Control Arm

- Worn-out Bushings

- Faulty Ball Joints

- Deteriorated Tie Rod Ends

- Compromised Struts

- Defective Shocks

- Flawed Mounting Hardware

- Damaged Strut or Shock Pistons

- Weakened Suspension Springs

- Loose or Broken Stabilizer Bar Links

- Malfunctioning Wheel Bearings

- Insufficient Lubrication

- Improper Torque Settings and Misalignment

This article will discuss common suspension noises and their associated problem areas. We will also comprehensively explain the causes and their corresponding solutions.

Different Suspension Noises and Their Problem Areas

While the gist of this guide is about causes and fixes, I opted to include this non-exhaustive list since the suspension can be elusive and hard to visually inspect sometimes.

This makes it tricky to identify potential causes. Hence, it only makes sense to minimize the difficulty by being familiar with the common suspension noises and the systems or components they are linked to:

| Noise | Affected component |

|---|---|

| Knocking | Control arm bushings, struts, shock mounts, tie rod ends, stabilizer bar links, springs, ball joints |

| Squeaking or Creaking | Control arm bushings, sway bar bushings, strut or shock absorber bushings, strut mounts; Insufficient lubrication of suspension components or joints |

| Rattling or Clunking | Suspension mounting bolts, sway bar bushings, stabilizer bar links, shock absorbers, strut mounts, tie rod ends; Misaligned suspension components |

| Humming or Grinding (more frequently linked to transmission than suspension problems) | Differential or axle components, CV joints, wheel bearings; Misaligned/damaged brake components |

| Banging or Bouncing | Struts, shocks, shock absorber pistons, suspension mounting bolts, springs |

| Scraping or Rubbing Noise (typically a bad rotor symptom) | Brake components or control arm bushings; Contact between suspension components and other parts |

| Clicking or Tapping | Suspension components, CV joints, suspension mounting bolts |

| Vibration or Shaking | Suspension components, wheel bearings |

| Metal-on-Metal | Suspension components, bushings, or bearings; Insufficient lubrication in suspension joints |

Notice that a big chunk of what is in this list (if not its entirety) is similar to engine noises because the suspension works in conjunction with the system and many others.

If you are a less-experienced car owner, you may find it surprising that several of these noises are associated with suspension. For instance, squeaking noises are often associated with brakes more than suspension components. And yet, poorly-lubricated joints or a deteriorated sway bar bushing can cause the sound.

What Causes Noise from Suspension?

As highlighted earlier, the list of affected components above and factors like inadequate lubrication and poor vehicle upkeep are part and parcel of what causes suspension noises. But for a better understanding of the issue, let’s go over each of its problem areas in this section:

1. Damaged Control Arm

A-arms or wishbones connect the suspension to the vehicle chassis. They feature bushings and ball joints that enable controlled movement and flexibility.

These components are undeniably integral to maintaining suspension geometry in a four-wheeler. However, when compromised, they can lead to a slew of other issues — all contributing to suspension noise — as follows:

- Loose or worn-out ball joints

- Failed bushings

- Bent or twisted control arm

- Damaged mounting points

- Corrosion and rust

2. Worn-out Bushings

Rubber or polyurethane bushings isolate and absorb vibrations, serving as a cushion between various suspension components. But that is not their only role. They also prevent metal-to-metal contact, help maintain the alignment of components, and regulate suspension movement. Over time, however, they can wear out — this is when noise from the suspension occurs.

3. Faulty Ball Joints

Ball joints connect the control arms to the steering knuckles, enabling controlled movement and rotation. And being highly-stressed components, they are bound to develop problems eventually.

The most common is, perhaps, excessive play or looseness (where the A-arms and steering knuckles move more than they should and produce a clunking or knocking noise as a result). Other common faults with ball joints include misalignment, torn boots, corrosion, and contamination.

4. Deteriorated Tie Rod Ends

Tie rod ends are a shared component — in the sense that they serve a crucial role in both suspension and steering systems. While they are categorically part of the suspension, symptoms manifest more in a vehicle’s tire-and-wheel assembly when something goes wrong with this component.

Common telltale signs include steering vibration, front-wheel misalignment, and excessive tire wear. Depending on the severity, noise from the suspension may not always accompany these issues.

5. Compromised Struts

If you hear suspension noise over bumps, you may have faulty struts (view on Amazon). This is because these parts are built to support the chassis and allow for articulation and strut rotation while reducing shuddering and noise from the suspension.

Squeaking, creaking, or knocking can be heard when the strut or its mounts are damaged. But hearing these noises — specifically when driving over bumps or turning — calls for inspection of the upper mounting plate and upper bearing assembly.

6. Defective Shocks

Worn-out or malfunctioning shock absorbers can create knocking or rattling sounds. In this scenario, rear suspension noise over bumps or uneven surfaces is typically observed.

But this is not the only thing you should be worried about, as worn or damaged shock absorbers can translate to reduced maneuverability and on-road safety — on top of an uncomfortable ride.

7. Flawed Mounting Hardware

Suspension mounting hardware includes various components such as bolts, nuts, washers, and brackets that secure the suspension components to the vehicle’s chassis. When these hardware elements are loose or damaged, problems like wear, fatigue, and misalignment — even insufficient hardware — can generate rattling or metallic clunking noises.

8. Damaged Strut or Shock Pistons

The pistons inside struts and shock absorbers are as equally significant as the components they are part of. When it comes to noise from the suspension, they may be an even greater trigger than the struts or shocks themselves.

Pistons have seals that, when damaged, can lead to fluid leakage around the piston (which immediately affects strut or shock performance), resulting in reduced damping capabilities and noises like squelching, hissing, or gurgling.

9. Weakened Suspension Springs

When a suspension spring cracks or breaks, its broken section may move independently or come in contact with other components, causing banging, clunking, rattling, or scraping sounds. This outcome could be driver-induced. But there are instances where natural wear and tear causes the coil springs to weaken over time and bind.

10. Loose or Broken Stabilizer Bar Links

While compromised sway/stabilizer bar links produce the same rattling or clunking sound, there is one way you can tell them apart from other root causes of noise from the suspension — they are mostly heard during cornering or when making sudden maneuvers. It is just a matter of whether the suspension noise comes from the front or rear of the vehicle (depending on where the faulty sway bar link is located).

11. Malfunctioning Wheel Bearings

Wheel bearings (view on Amazon) malfunction when worn or damaged. They also produce many unusual sounds during that time, including grinding, growling, humming, whirring, clicking, and snapping.

These noises result from the damaged bearings creating friction against the rotating hub or spindle. Also, they are typically speed-dependent and may intensify during turns or corners.

12. Insufficient Lubrication

Lack of proper lubrication in suspension joints, such as ball joints or control arm bushings, can lead to squeaking or creaking noises. The same is true for any other moving suspension part, as improper lubrication is bound to result in grating during suspension movement.

13. Improper Torque Settings and Misalignment

Excessive play/looseness and misalignment are in most descriptions in this list because they are among the top reasons noise from the suspension would even occur. They are part cause and part outcome. But sometimes, they can also be due to negligence.

When suspension components are not regularly inspected and properly serviced, they are more likely to develop slack and become misaligned. Either that or the vehicle owner neglected to follow OEM instructions regarding correct torque settings and installation.

How to Diagnose a Suspension Noise

Once you have determined the cause of the noise from the suspension, appropriate repair or replacement can be undertaken. This process may involve replacing worn-out or damaged components, tightening loose bolts, lubricating relevant parts, or realigning misaligned components (among others).

Now you have two ways to determine which route to take. First, you take your four-wheeler to an auto repair shop and have them sort through the mess. Or second, you do it yourself following the below guidelines:

Prepare

Get your service manual and all your tools ready. Also, do some ‘light reading’ on relevant TSBs. Who knows? You may not even have to diagnose if the issue is a manufacturing flaw. Otherwise, at least you have everything you need for the job.

Here is a list of tools that usually come in handy for this kind of task:

- Dial indicator

- Digital Multimeter

- Floor jack like Blackhawk Telescopic Transmission Jack (view on Amazon)

- Four-post/alignment lift

- GoPro camera

- Jack stands

- LED lighting

- Pry bar

- Steelman Smart Ear (for ‘traveling’ suspension noises)

- Tape measure

- Temperature gun or probe

Analyze

Collect relevant information about the specific nature of the suspension noise, when it occurs (during driving, turning, braking, etc.), and any other symptoms or observations noticed.

Inspect thoroughly

Inspect the suspension components thoroughly, including shocks, struts, control arms, bushings, ball joints, and stabilizer bar links. Look for any visible signs of damage, wear, or loose connections.

Check for discrepancies in ride height at the front and rear (usually indicative of worn struts, springs, or mounts). Include inspection of your car’s steering system and relevant components as well.

Replicate the noise

Test drive to replicate the noise from the suspension. Consider specific conditions that trigger the noise, such as bumps, turns, or braking.

Also, watch for unusual car behaviors or differences in temperature between wheel hubs after the test ride. Different temperatures and a whining noise while driving usually indicate a potentially faulty hub bearing.

All your observations should help you narrow down suspected suspension components creating the sound (if only slightly).

Assess each component

Raise your vehicle on a lift or use jack stands to better access the suspension components you plan to inspect. Assess each closely for any signs of damage, corrosion, or wear. Check for loose or broken parts and excessive play in joints or bushings.

Check the wheel bearings

When inspecting wheel bearings for any play or roughness, jiggle the wheel side to side and up and down. Listen for any grinding or rumbling sounds while rotating the wheel by hand.

Check the bushings and mounts

Similarly, check the bushings and mounts of the suspension components for signs of wear, cracking, or deterioration. Use a pry bar or leverage tool to check for excessive movement or play in the bushings.

Inspect the ball joints

For ball joints, apply pressure or use a ball joint press tool (view on Amazon) to check for excessive play. Look for torn or damaged rubber boots and listen for clicking or popping sounds while maneuvering the joints.

Examine the stabilizer

Examine the stabilizer or sway bar links for any signs of damage or wear. Likewise, inspect rubber bushings and joints for cracking, tearing, or looseness. Apply pressure to check for excessive movement.

Check for leaks and damage

Inspect for leakage, damage, or wear regarding struts and shock absorbers. Manually compress and extend each strut or shock to check for smooth operation and resistance. And take note of any signs of oil leakage.

Once potential problem areas have been identified, re-attempt replicating the noise by applying pressure, shaking components, or simulating driving conditions. You may need to re-do these steps until you can confidently say the suspected part is indeed causing the sound. You can then proceed with repairs or replacements.

In doing replacements, ensure that the component, locking nut, and mounting hardware are all brand-new. This way, you can make sure to follow OEM-recommended tightening torque specs.

The same principle applies to shocks but with slight nuances. Especially for shock absorbers utilizing a clevis-type mount, it is important that the brackets do not get spread apart excessively (in addition to ensuring their ‘mounting sleeve’ is tightened very securely).

Conclusion

Note that the contents of this guide are focused on suspension components that may be potentially responsible for the unusual sounds. But in truth, noise from the suspension is not confined to suspension components alone.

Whenever you hear your four-wheeler emitting suspension noises, there are at least three systems you will need to immediately check — your suspension, steering, and tire-and-wheel assemblies.

It is still best to refer to your service manual for specifics on addressing suspension noises — whether it is a DIY task or outsourced to a professional.

Kris is an avid off-roader and outdoor enthusiast who loves to brave the elements and take on challenging terrain. He also enjoys sharing his passion and knowledge with others so that they, too, can appreciate the ride.

About Kris